Most laboratory professionals understand that it is imperative to follow the instructions of the manufacturer’s site preparation guide in order to avoid system malfunctions and maximize the throughput and productivity of new sequencers, Gas-Chromatography/Mass Spectrometers (GC/MS) and other scientific instruments. Typically, there is a significant investment of capital in the system, its installation and operation. Operational costs include reagents, test samples and the scientist man hours. Ideally, these systems are set up to operate (with clean power) for five to ten years and even longer, which is extremely important to government agencies and organizations that operate on tight budgets. To help meet the equipment manufacturer’s site preparation recommendations, this paper will focus on often overlooked or misunderstood power quality requirements of laboratory equipment.

Don’t Take Chances with the Power Grid

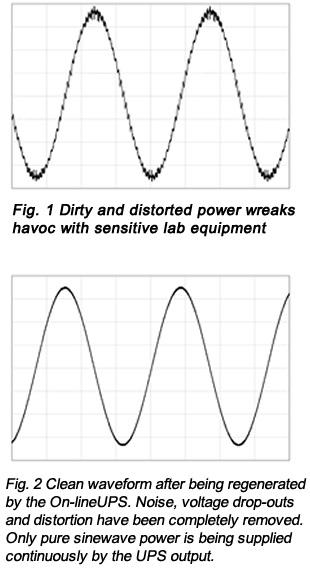

There are a number of important issues that must be addressed by lab professionals weeks before their new equipment arrives to assure smooth implementation. One of the most vital issues is to assure that the lab’s AC power is clean and stable to power the new equipment. There is often a common assumption that AC power coming from the wall outlet is reliable (clean power). But after one damaging power event, like an outage, one becomes aware of the precarious nature of the power grid. Other damaging power anomalies, such as harmonics, high voltage transients and surges, are not as obvious as blackouts, but can cause serious equipment performance and reliability problems that may arise several months later.

Furthermore, generator backup systems fall short of the power quality demanded by sensitive laboratory instruments. Generator systems are unable to protect against poor power quality, have unstable output frequencies and create switchover dropouts when the utility power is lost.

Selecting the Right Power Protection

In order to protect equipment from these costly power problems, many equipment manufacturers specify the use of an uninterruptible power system (UPS). Most site preparation guides that specify UPS installation frequently do not specify the UPS type and quality level that is required to meet their equipment’s demanding needs. The Institute of Electrical & Electronic Engineers (IEEE) defines UPS topologies in the following categories: “Off-line,” (“or Standby”) “Line-interactive” and dual-conversion “Online” (commonly known as “double-conversion”). Due to the sensitive nature of lab instruments, a double-conversion Online UPS is the best choice since it solves the widest spectrum of power problems. Line-interactive and Standby UPS, while more economical, do not provide the high level of power protection and conditioning demanded.

The difference between these UPS topologies is often not clearly understood. About 90% of the UPSes on the market today are actually Standby or Line-interactive designs. These battery backup units are low–cost and designed to address the basic backup needs of home PCs and office computers. They leave the equipment connected directly to the power utility source until power is lost and then switch over to the inverter, creating a 10 to 20 millisecond drop out during the switchover. This may be acceptable for PCs, but not for sensitive laboratory equipment.

Furthermore, the Line-interactive UPS or “Smart UPS” incorporates a boost/buck automatic voltage regulator (AVR). This provides a crude method of output voltage regulation when the UPS is operating from utility power. To accomplish this, the AVR senses the utility voltage and when out of a ±8 to 12% nominal voltage range, switches transformer taps in an attempt to keep the output voltage within acceptable levels. This is actually a band-aid approach and often causes more problems if used with laboratory instruments. Unfortunately, the AVR feature does not provide the continuous ±2 to 3% voltage regulation needed by the equipment. Additionally, the AVR must switch to battery mode to make transformer tap changes. This switching causes excessive battery cycling and reduces overall UPS battery life, resulting in costly premature battery replacement.

By contrast, the double-conversion Online UPS regenerates totally new sinewave power both in utility and battery backup modes. It converts the incoming AC power to DC, then filters and regulates it, and finally regenerates clean, new tightly regulated AC power. This active approach assures superior ±2 to 3% output voltage regulation and provides the highest level of power conditioning demanded by sensitive laboratory equipment. Additionally, in contrast to Standby and Line-interactive UPS designs, the On-line UPS only uses battery power when utility power is not present. Therefore, battery life is typically much longer than other UPS topologies. The Online UPS has no disruptive switchover drop when utility power is lost or restored. Most new Online UPSes also provide input power factor correction. This greatly reduces harmonics that may adversely affect building wiring and other equipment operating inside a lab.

Finally, another feature available with some Online UPSes is galvanic isolation. This eliminates neutral-to-ground and common mode noise paths, as well as ground loops by electrically isolating the instrument to increase accuracy and data communications reliability. In most cases, an Online UPS will solve the power problem but if the issue is due to faulty wiring, an isolated Online UPS will address the absence of proper grounding in the area.

Conclusion

By the nature of a laboratory environment, the work being performed is exacting. The reliability of lab equipment and its test results must be absolutely assured as a lab’s credibility may be at stake. Laboratory professionals should not take the unnecessary risk of ineffective power protection, and instead should protect all key laboratory equipment with a high quality, double-conversion Online UPS.

Engineering Department

Falcon Electric, Inc.

© Falcon Electric, Inc.

All Rights Reserved